Welding:

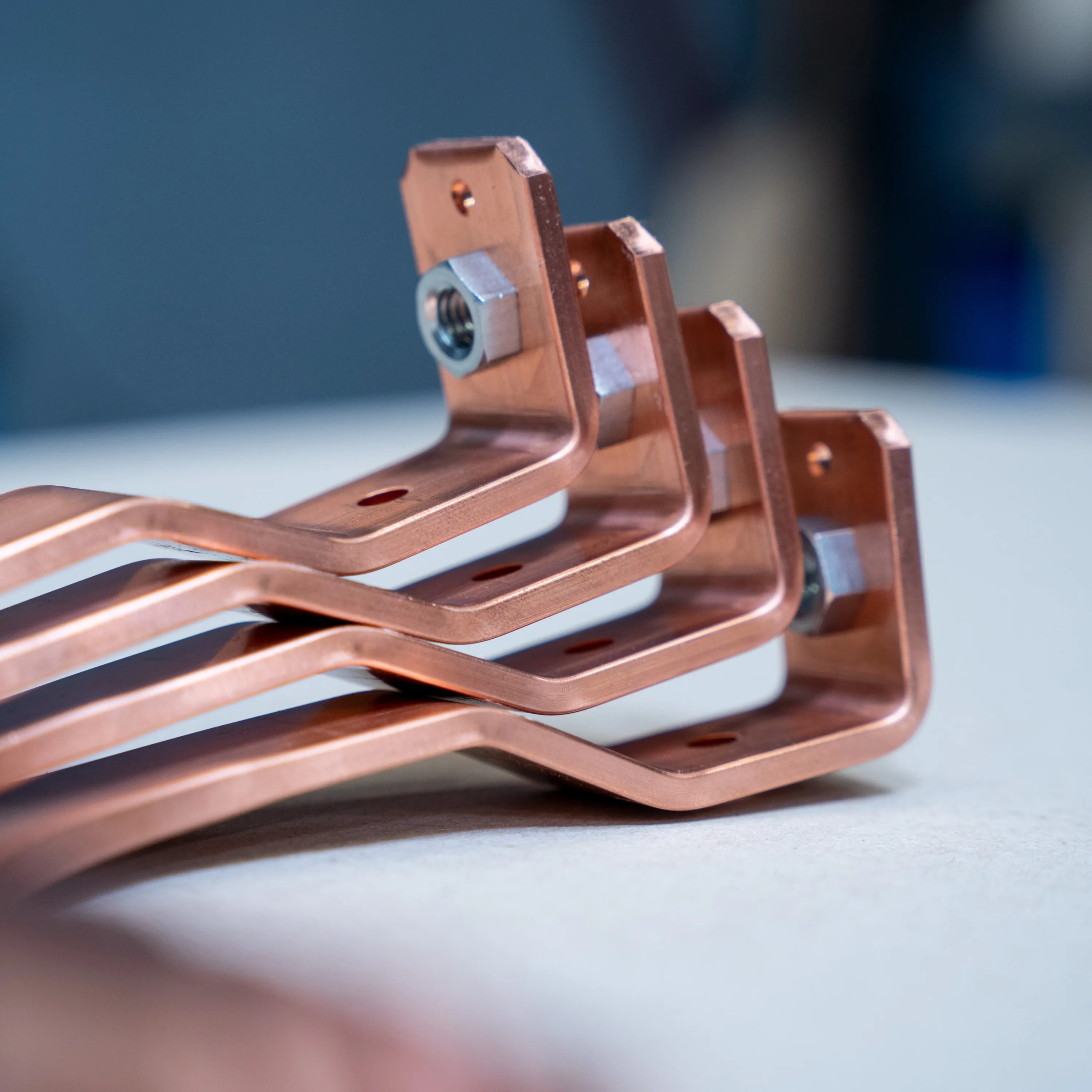

From components to complete solutions

Whether it's a housing, a structural frame, or a complete finished product: Dumaco is your partner for assembling sheet metal, tubes, and machined parts into the desired product. With a large team of certified welders, specialized expertise, and multiple production locations, we deliver high-quality welded joints for both one-off and series production, fully tailored to your specifications.

Reliable welded construction

At Dumaco, we combine skilled craftsmanship with advanced technology to deliver strong, precise, and reliable welded constructions. From simple components to complex assemblies, our specialists ensure quality and durability in every detail. By bringing welding and assembly together under one roof, we offer complete solutions tailored to your project.

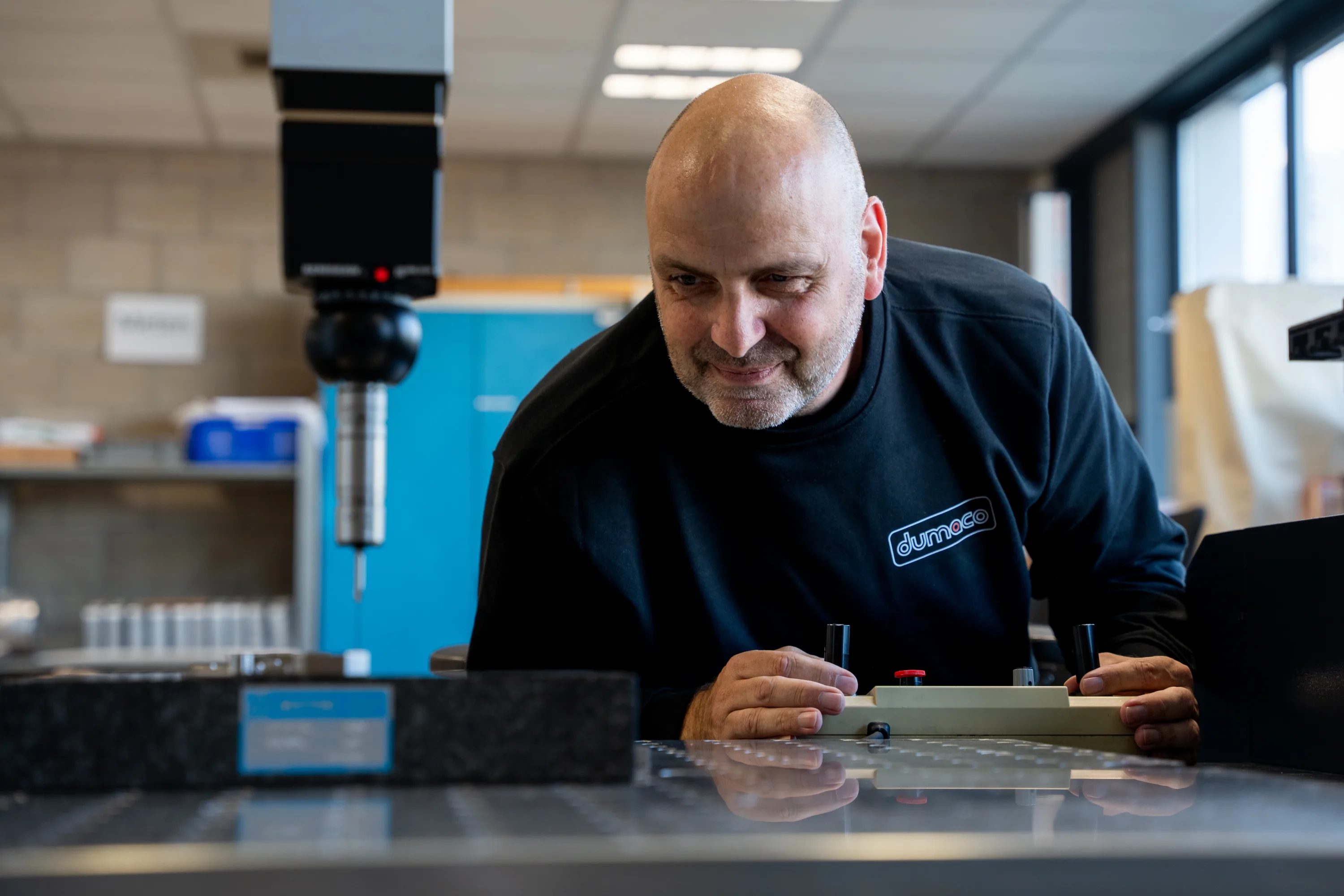

Welding with consistent quality and craftsmanship

Welding requires technical precision, material expertise, and experience. At Dumaco, we combine these factors with an efficient production environment and strict quality assurance. Thanks to our qualified manual welders and modern welding equipment, we can confidently perform this work for a wide range of sectors, such as mechanical engineering, construction, the food industry, and the medical sector.

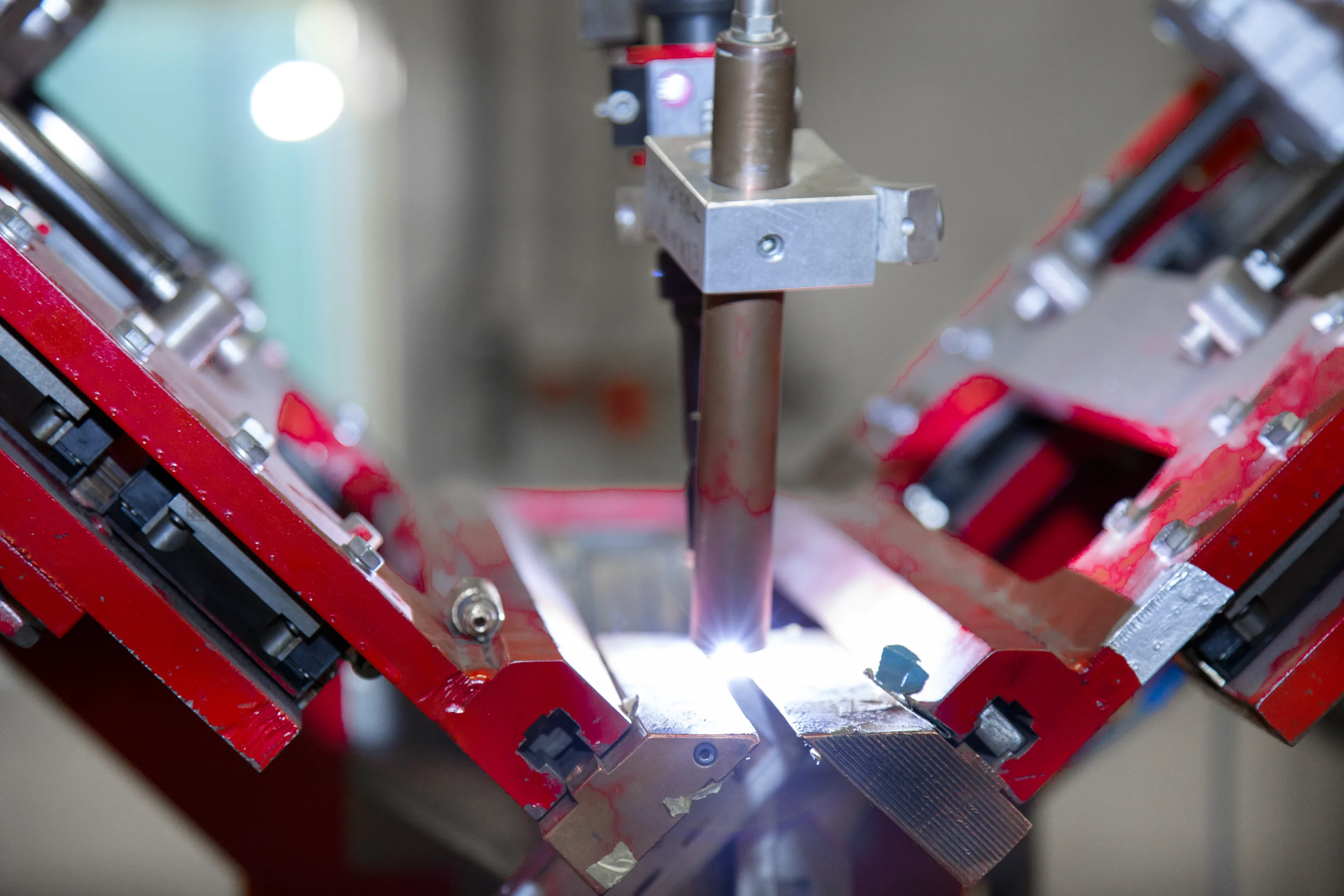

Whether welding steel, stainless steel, or aluminum, our specialists select the right welding method for each application and ensure a consistent finish with strong joints. We are proficient in TIG, MIG/MAG, spot, stud, laser, and robotic welding, depending on the material type, weld characteristics, and visual requirements.

From welding to complete product

Welding is often a key step in a broader production process. At Dumaco, we use this process as part of complete assemblies, semi-finished products, or finished products. Thanks to our wide range of processes, such as waterjet cutting, pickling, and powder coating, we are able to fully integrate welding into production planning.

This delivers immediate benefits: fewer handovers, shorter lead times, and higher delivery reliability. Moreover, from the engineering phase onward, we can contribute to the design of material thickness, welding sequence, and optimal weld seam preparation, for a more manufacturable and sustainable end result.

Dumaco assembles and welds

What makes Dumaco unique in assemblies

- Fully in-house: sheet metal working, tube processing, machining, welding, post-processing, and assembly

- Short lines of communication between departments ensure optimal coordination

- Certified welders on our team

- One point of contact from prototype to series production

- High reliability in delivery time, dimensions, and quality