Multiple processing:

for your project

From sheet metal and tube to semi-finished and finished product. From idea to (welded) assembly.

A comprehensive approach for large projects

Not every project starts with a detailed drawing. Sometimes there's only an idea, a need, or a rough sketch. In those cases, we're the partner who thinks along with you: technically, practically, and cost-consciously.

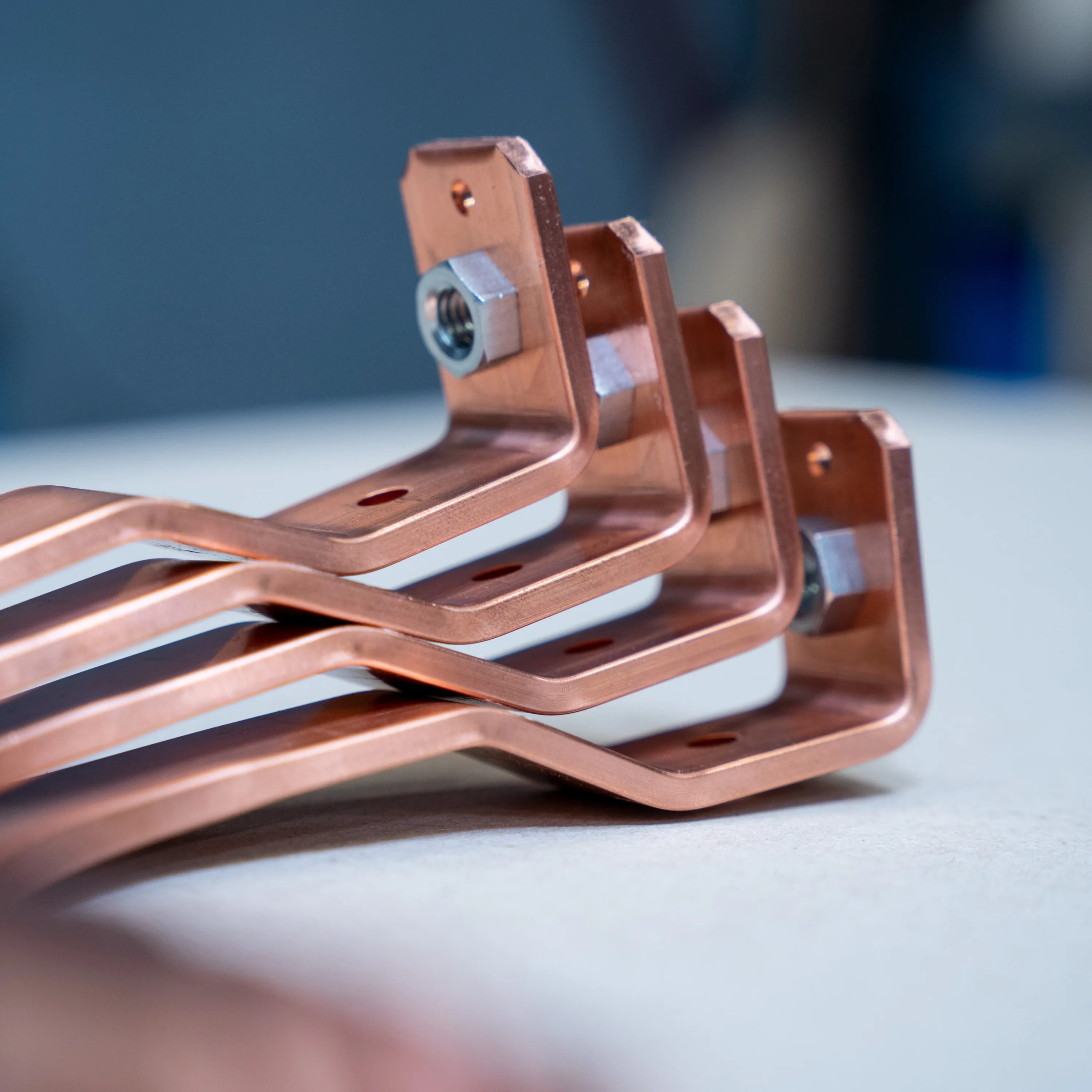

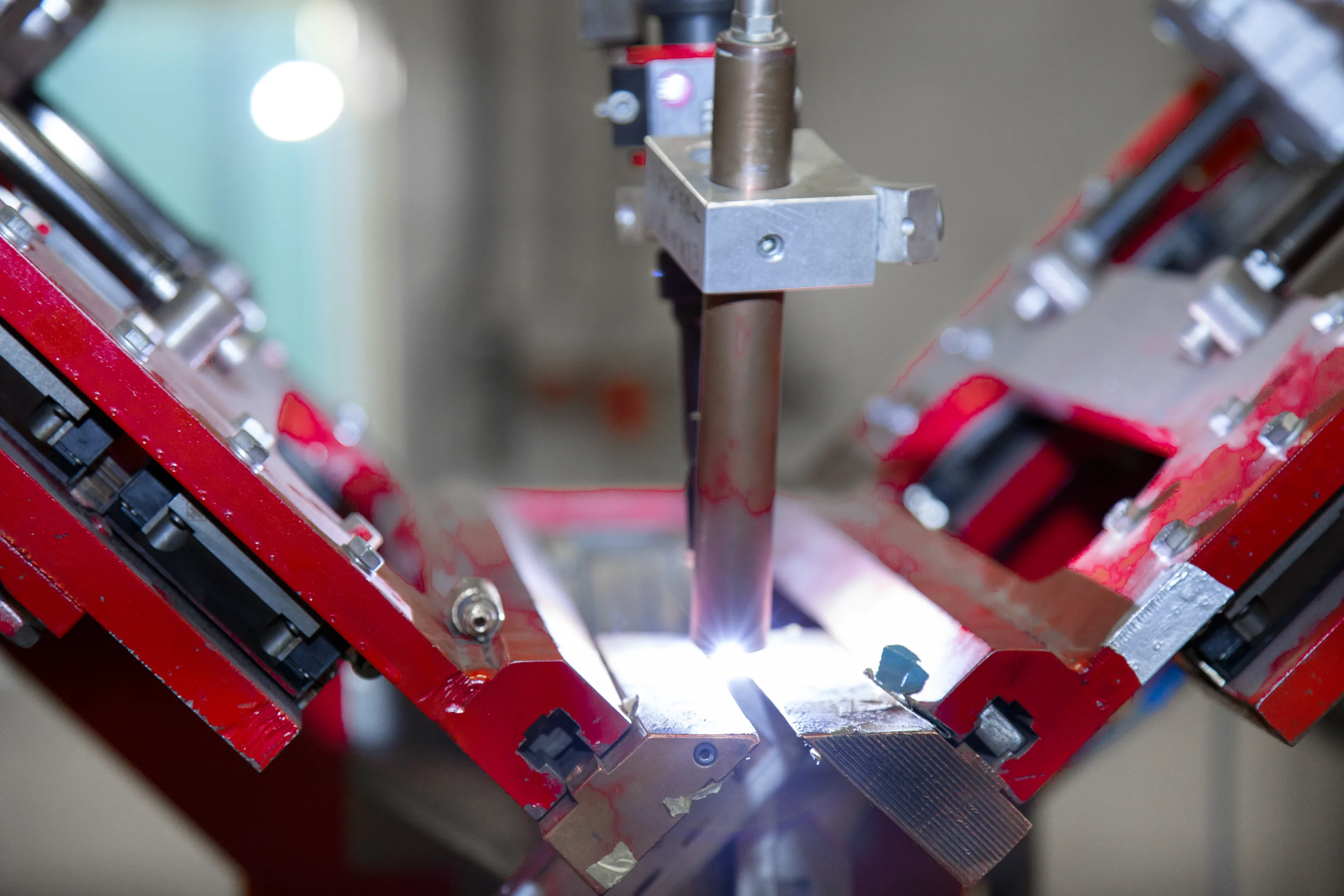

Metalworking processes in a single, integrated production process

We offer not only component machining but also the complete chain management: from (re)engineering to (sub)assembly. By combining various metalworking processes into a single, integrated production process, we guarantee efficiency and quality in your project. Think laser cutting and bending, machining, and the assembly and welding of components into complete semi-finished or finished products.

With our extensive machinery and team of 800 skilled professionals, we can realize even the most technically challenging projects, from start to finish. Challenge us with your project and schedule a consultation or quote today. We'll make your idea a reality.

Complete approach for large projects

Larger projects often involve more than just the machining itself. That's why we offer a comprehensive approach, including both engineering and project management. Our engineers often start with value engineering, optimizing the design for production. This ensures your project is executed optimally, technically, economically, and practically. This can be achieved, for example, through:

- Technical optimization for manufacturability and material efficiency

- Alternative material use for improved performance or cost savings

- Smart construction details that ensure ease of assembly and reduce failure costs

Through this integrated approach, we combine technical expertise with practical feasibility, ensuring your project is completed smoothly, efficiently, and with the highest quality.

Project-based approach with a single team and a single point of contact

For larger projects, we assemble a multidisciplinary project team consisting of specialists from our production, engineering, and project management departments, supplemented by key individuals from your organization. This team oversees the entire process, from initial specifications to final delivery. We typically begin the project with a kick-off meeting, where we make clear agreements, define objectives, and establish the schedule. During implementation, we maintain short lines of communication and open communication. This way, you always have control over progress, planning, and quality.

What you can expect from us

- One point of contact, one partner

We take full responsibility for the entire process: from technical advice and re-engineering to the final product. No separate links, but a single partner who contributes ideas, makes adjustments, and ensures that everything is correct, in every project phase. - Scalable production capacity

With over 800 specialists and multiple production locations, we can easily produce large, complex, and long-term series. Whether it's total purchase or delivery in partial series, we guarantee continuity and security of supply. - Direct communication with short lines of communication

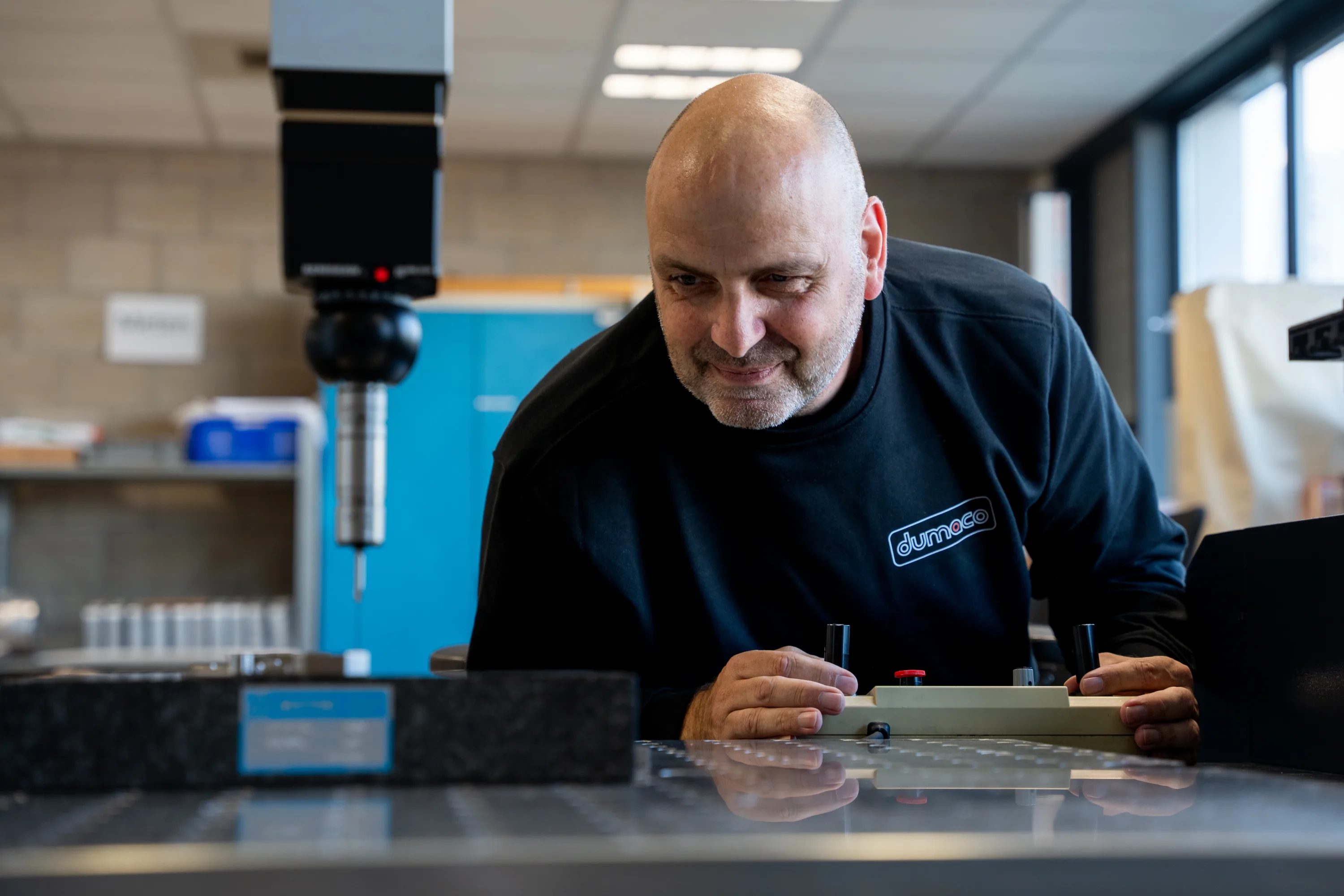

With us, you always speak directly with specialists who are familiar with your project. No unnecessary lead times, just quick decisions and clear communication. We assemble a multidisciplinary team where necessary, allowing us to quickly respond to changes and challenges. - High quality and welding certifications

Quality is always our top priority. We work according to strict quality standards. Our experienced welders deliver craftsmanship, and even for projects with mandatory certifications, we can fully meet the requirements. Thanks to our advanced 3D measuring chamber and cleanroom, we guarantee that even the most complex parts and assemblies are delivered with the utmost precision. - Full chain management

From the initial technical consultation to final assembly, we take care of everything for you in every phase of the project. This includes value engineering, 2D and 3D drawings, strength calculations, design optimization, and prototyping.