Machining:

From turning and milling to grinding

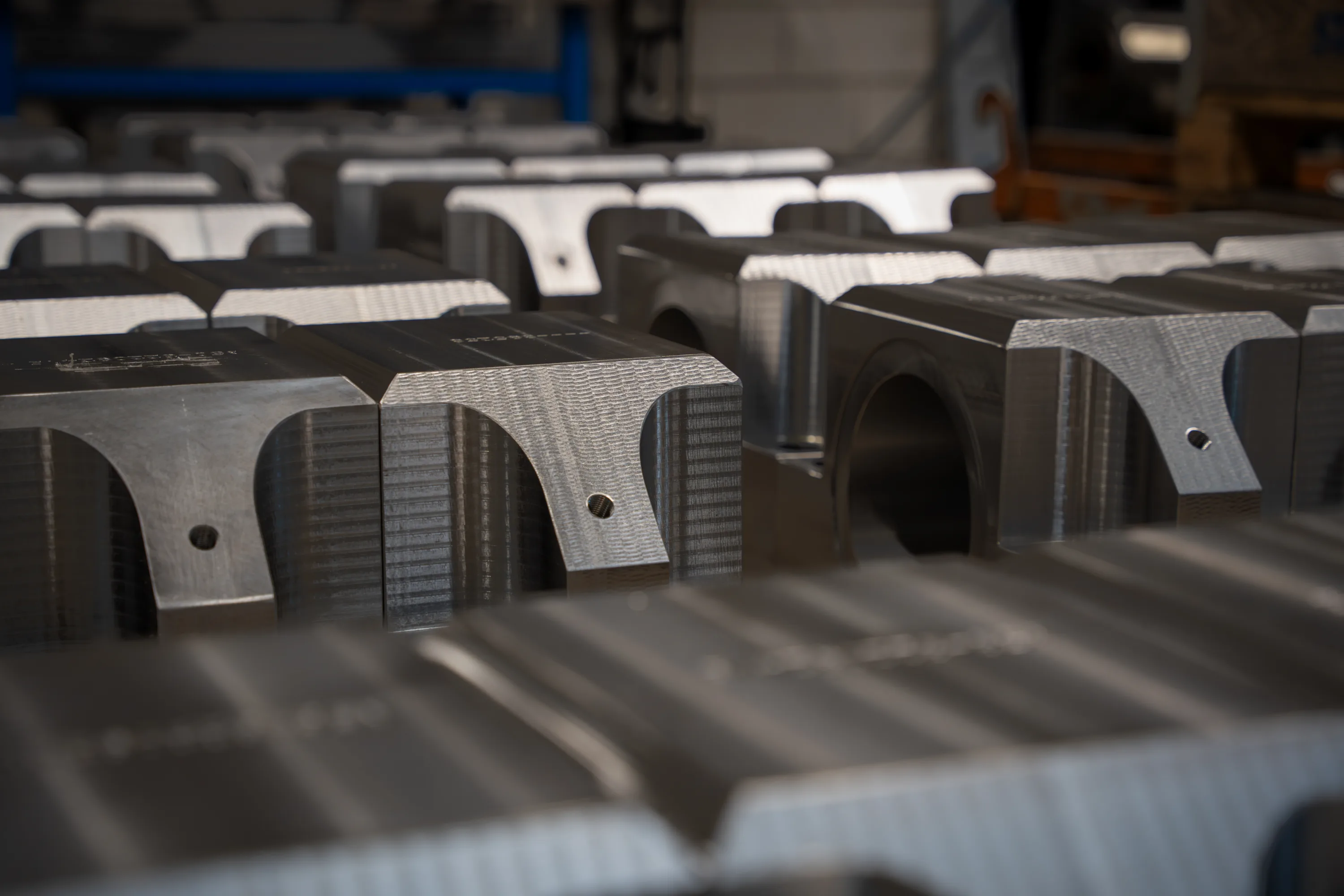

Dumaco is the specialist in machining exotic materials up to 70 HRC, with machining in the micron range and machining up to 20 tons. From precision components to large-scale machining: we combine engineering with precision machining. Everything under one roof.

Turning, milling and more

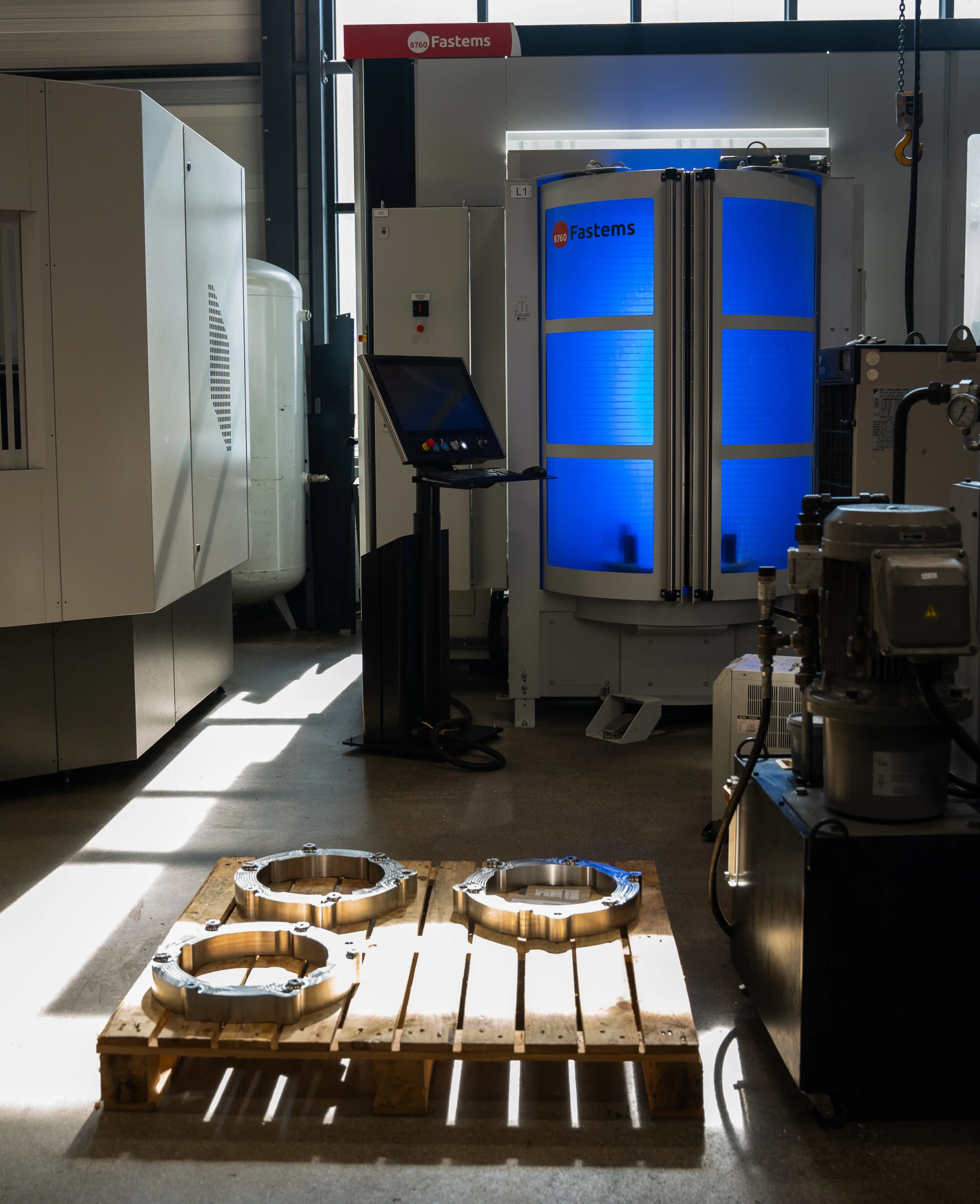

With advanced turning and milling techniques, Dumaco produces high-precision components that meet the highest standards. From one-off custom parts to large production runs, our skilled specialists and modern machinery ensure accuracy, consistency, and efficiency throughout the process.

One partner for all your machined parts

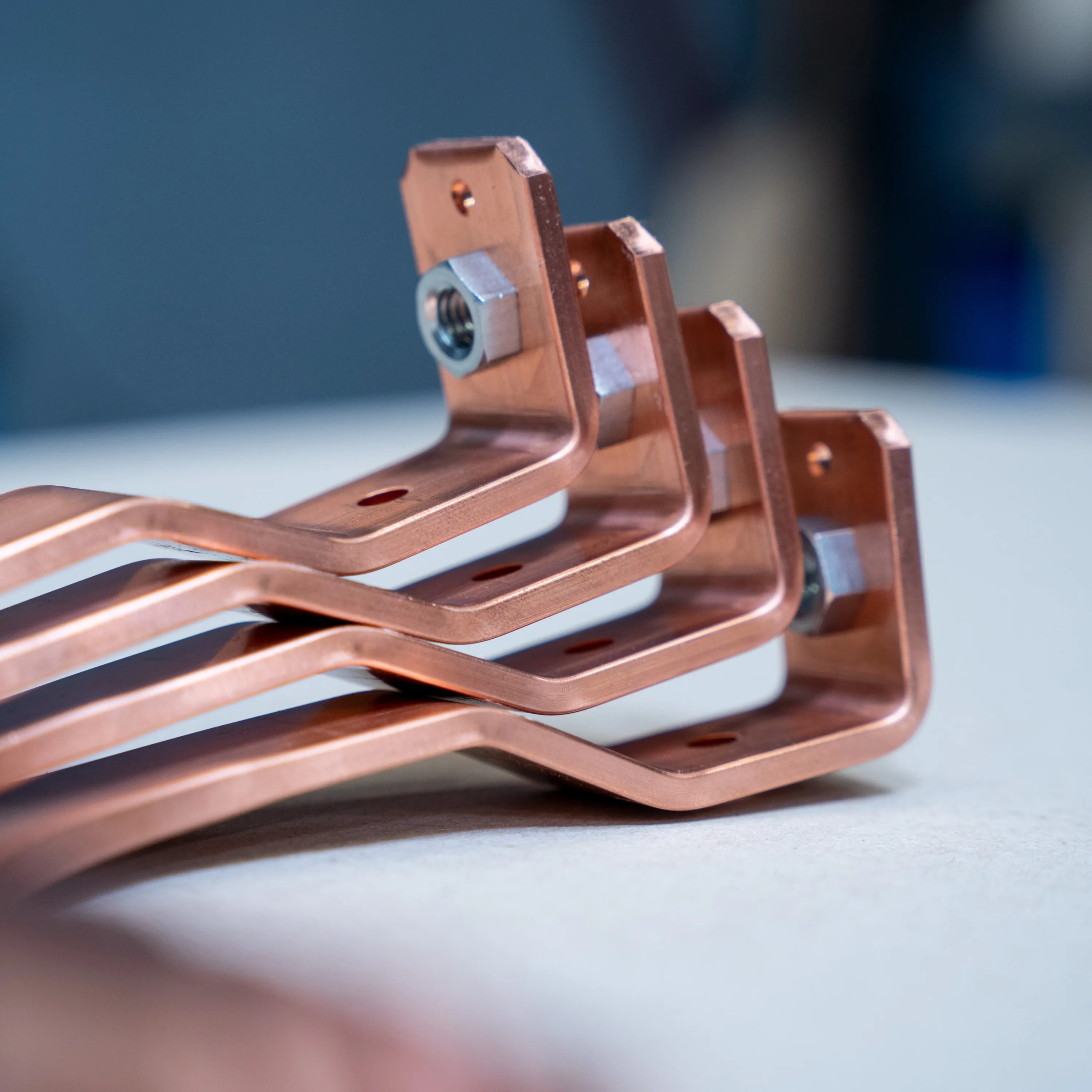

Whether you need to turn a titanium flange or grind a precision component, Dumaco is the right place for you. We also offer wire EDM and honing, allowing us to provide a complete range of machining services. As metalworking specialists, we have a wide range of techniques, machines, and skilled professionals, all under one roof. From microscopic components to parts 12 meters long and 4 meters high, we handle the entire spectrum.

Our machining capabilities:

- CNC turning from a diameter of Ø 5mm up to a diameter of Ø 4.30 meters and a length of 6 meters

- CNC milling from a diameter of Ø 5mm up to products 12 meters long and 4 meters high

- Surface grinding up to a length of 6 meters and a width of 1.08 meters

- Circular grinding up to a diameter of Ø 640 mm and a length of 6 meters

- Products measuring very small up to a maximum of 5 x 3 x 2 meters

- Wire EDM, milling, and tumbling

Materials we machine

We machine virtually all types of metal and plastic, including: stainless steel, aluminum, (surgical) steel, titanium, Inconel 718, tungsten, Invar, lead, Kovar, armored steel, duplex, and plastics. Even if your desired material is not listed here, we sometimes machine custom materials upon request.

Why choose Dumaco for your machining?

At Dumaco, you're choosing more than just machining. You're choosing a partner who thinks along with you, delivers quality, and is reliable in every step of the process. What sets us apart:

- Full in-house supply chain: From engineering to post-processing and assembly, Dumaco offers a complete solution. Your machined parts fit perfectly into the overall product or project.

- Modern machinery, top-level craftsmanship: We continuously invest in our machinery and our people. With advanced CNC technology and years of experience, we deliver products with high accuracy and consistent quality.

- Large and small series possible: Whether it's prototypes, small quantities, or series production, we adapt flexibly. Our processes are designed for both customization and upscaling.

- Guaranteed quality: With strict controls and certified processes, we guarantee the quality you expect. Every machining operation meets the technical requirements and agreed-upon tolerances. Our processes meet strict quality standards, and we hold multiple certifications.

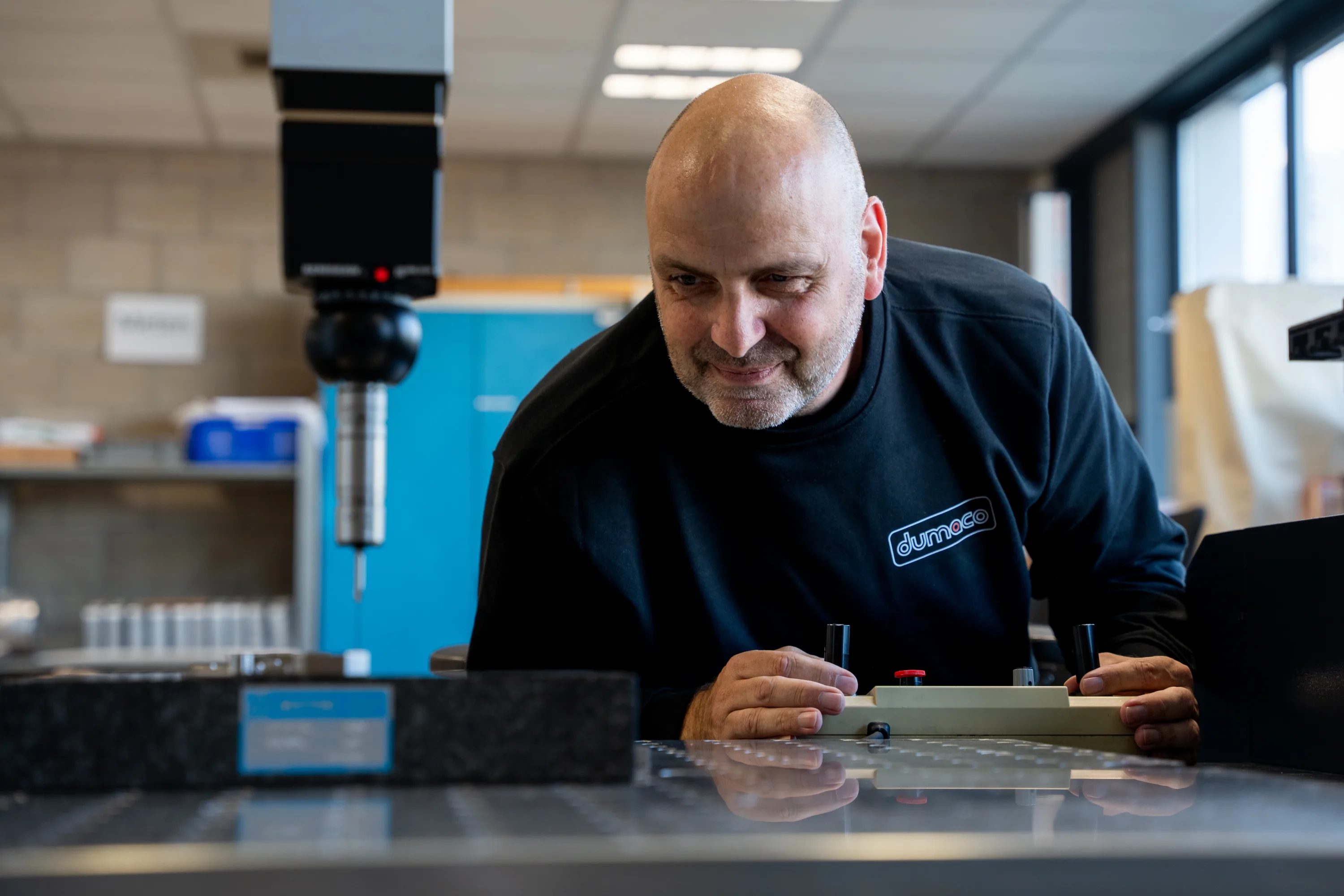

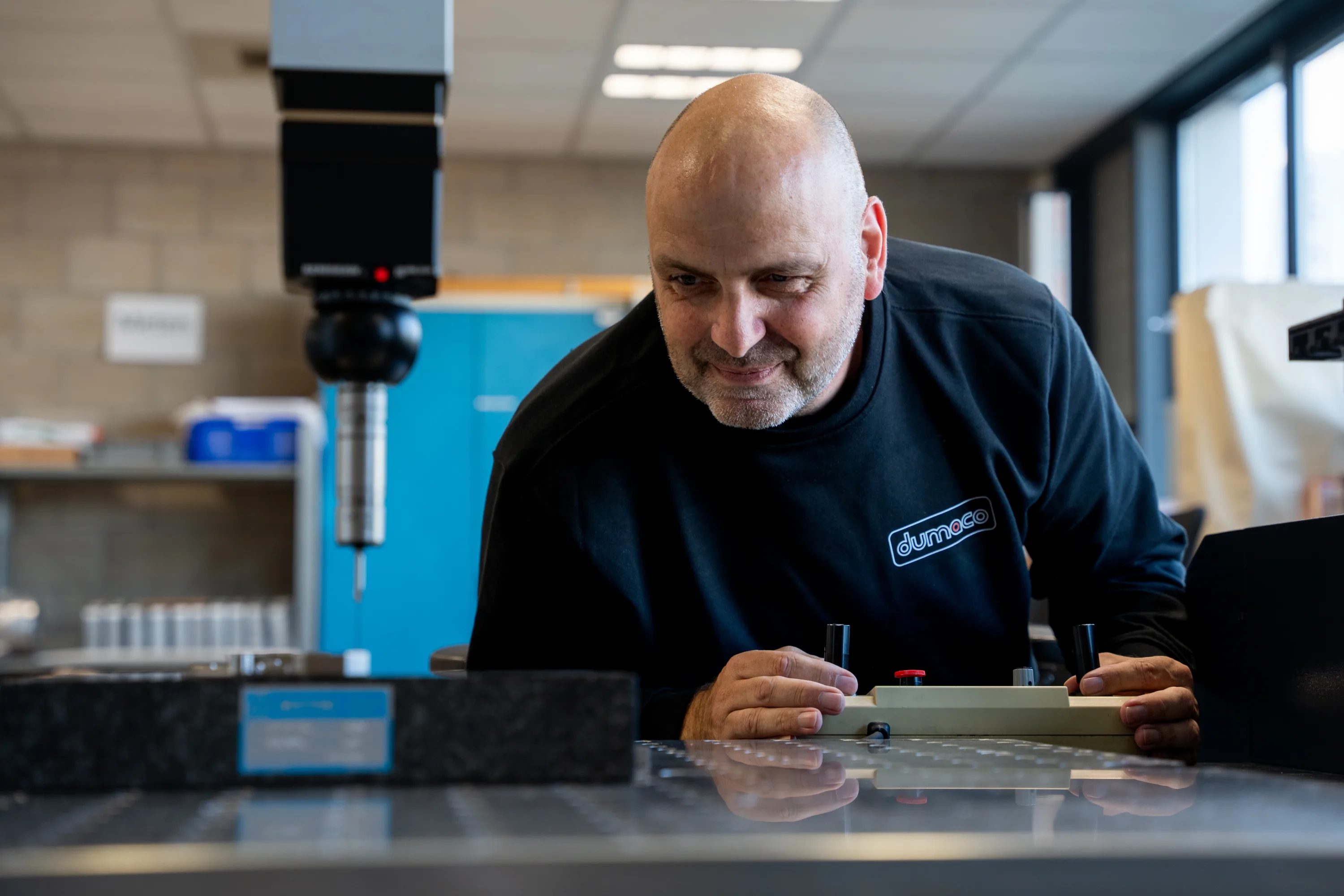

- In our climate-controlled measuring room, we perform precise measurements using advanced 3D measuring instruments. This ensures your components meet the highest tolerance requirements.

- For assemblies where cleanliness and control are crucial, we have our own cleanroom. Here, we assemble components dust-free and under constant conditions. Ideal for applications in the optical and medical industries, where absolute cleanliness is required.

Our approach: trust through craftsmanship

Precision machining and large-scale machining is more than just technology. It requires insight, collaboration, and flawless coordination between preparation and execution. Whether it involves turning, milling, grinding, or multitasking: at Dumaco, we seamlessly align technology, materials, and people.

You'll work with a dedicated team of specialists who oversee your project. From engineering and fixture construction to quality control and delivery. We identify manufacturing risks early on, contribute to tolerances, and ensure that every component, regardless of the machining, fits seamlessly into your assembly.

This is how we work towards reliability and continuity

- Smart clamping systems & in-house fixture construction

- Interim dimensional checks and final inspection with a measurement report

- Seamless integration with welding, milling, and assembly departments

- Series or project-based production, tailored to your schedule

Verdiep je in onze technische expertise

Ga naar alle artikelen