Copper processing at Dumaco

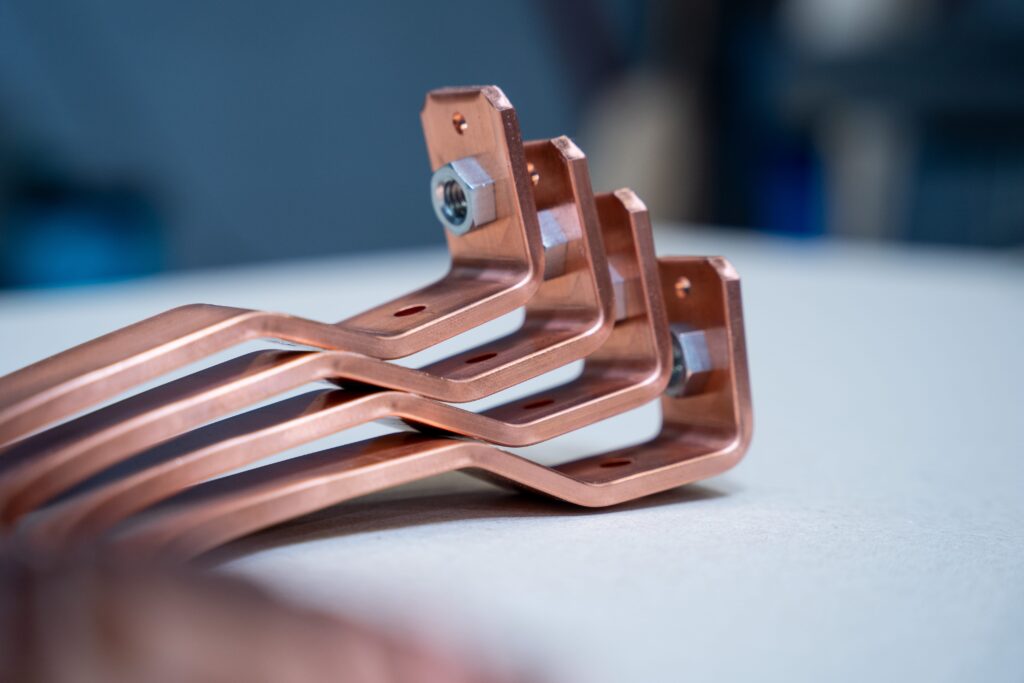

Dumaco is the leading supplier of copper and has all the knowledge, experience and machines necessary for copper processing. Copper is processed at our production site in Kampen. Dumaco Kampen will guide you carefully throughout the production process for your product. You will provide us with a Step, PDF, JPG or other file type. We will then use it to create the appropriate drawing and ensure you get the product you have in mind. So, we stand out from other companies by offering you the engineering you need as well.

Dumaco has a big production capacity for copper processing. Our high-quality machine pool enables us to provide you with high-precision copper processing work. We can galvanize and tap copper too. Feel free to contact us for more information about the options we are able to offer.

Dumaco provides a number of copper processing techniques

- Punching

- Laser cutting

- Drilling

- Milling

- Galvanizing

- Tapping

- Bending and folding

- Edge bending

- Press-nut fitting

- Code stamping

- Nickel plating, tin-plating and silver-plating (external)

- Final checks

Applications & markets

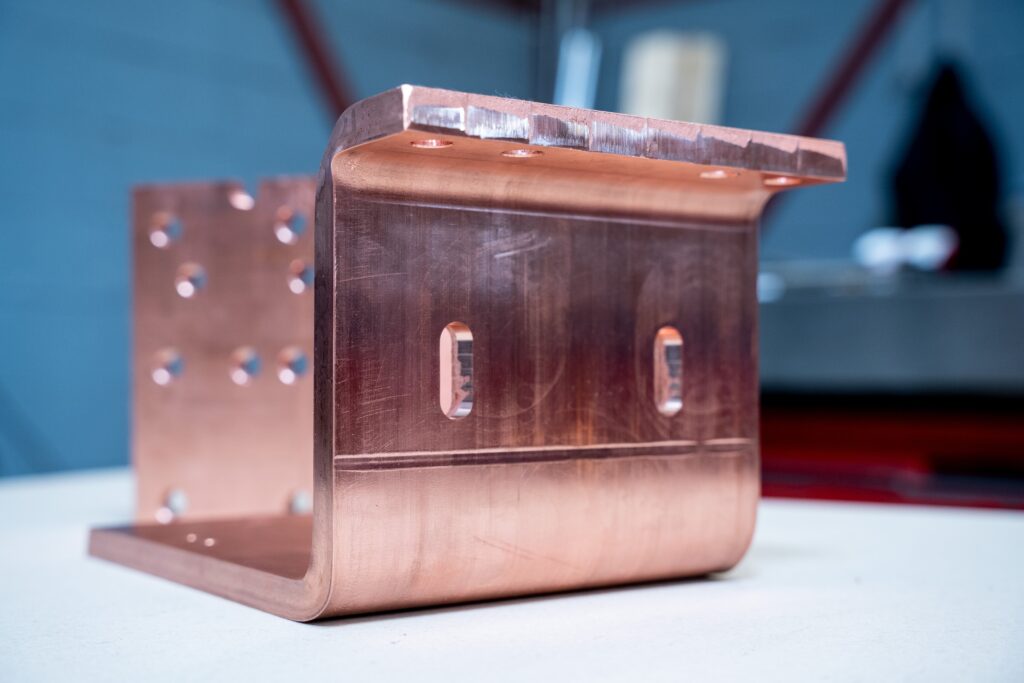

Dumaco produces and supplies customer-specific electric conductors and power distribution components made from copper, aluminum and brass for various market segments. For example, Dumaco supplies a number of big companies that are active in the electrical industry. This industry makes special demands – in respect of electrical conductivity in applications, for example. Copper is a material that is widely used to achieve electrical conductivity. Dumaco is able to produce a wide range of copper products for the electrical industry. We use our strip punching machine and CNC-controlled drilling center to process copper.

Several products that we have supplied to the energy industry relate to panel building, transformers, stations and mobile generators. Copper is only used when absolutely necessary because it is an expensive material. Besides the electrical and energy industries, copper is regularly used in the shipping and infrastructure industries. We supply a range of finished and semi-finished products in these market segments too.

Applications:

- Panel building and control panels

- Transformers

- Electrical systems for the shipping industry

- Generators

All the advantages at a glance

| In-house engineering |

| Machines suitable for single-piece and series production |

| High dimensional accuracy |

| Short delivery times |

| Modern machine pool |

| Green production via solar energy |

| Guaranteed quality because every product is checked |

| Possibility to code and/or label products |

Copper processing

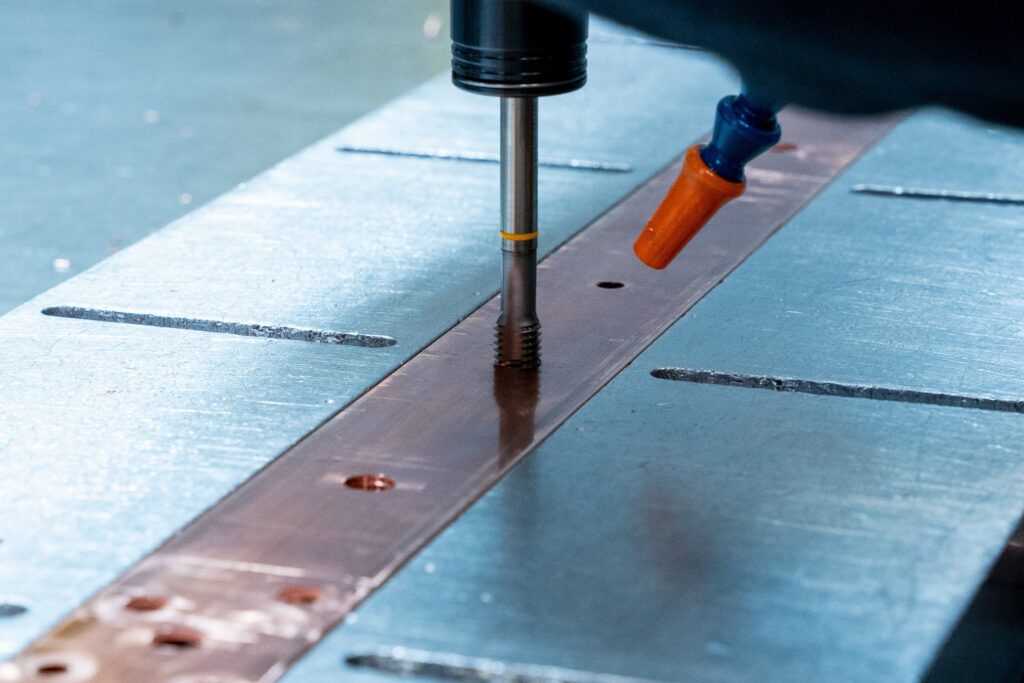

Machine in the spotlight: Ehrt FlexPunch

In 2020, Dumaco Kampen invested in a new Ehrt FlexPunch machine. This compact strip punching machine has been developed specifically for copper processing. Ehrt is a prominent brand for copper machines. The FlexPunch is the result of almost 40 years of copper-processing-machine development. The latest software makes it possible to optimally nest copper strips in the machine.

Our strip punching machine is able to process copper and aluminum from 15×3 mm up to and including 200×20 mm. So, it is able to accommodate a wide range of strips. The machine also has an automatic tool changer. It makes it possible to punch different holes in just one setup.

Our machines

For its activities in the electrical industry, Dumaco invested in a special strip punching machine (designed specifically for copper and aluminum) and also in a CNC-controlled drilling machine for thicker strips.

Armed with these machines, Dumaco can process copper into any shape required. The punching of copper has a number of advantages over a drilling or milling processing technique when thin strips need to be produced in series. Drilling or milling is more efficient than punching when thick strips are to be processed in a small series.

Our machines:

- Ehrt strip punching machine

- CMA CNC-controlled drilling center

- Bystronic laser

- Stierli bending machine

- Safan & LVD press brakes

- Dynobend bending machine

Standard quotations are always issued within 24 hours

Standard quotations are always issued within 24 hours