Tube-laser cutting at Dumaco

Just one company can be the biggest provider of tube-laser cutting. And that’s Dumaco! We are able to process your tubes and pipes at three sites (Oss, ‘s-Gravenpolder and Hardinxveld-Giessendam), with dimensions up to 8500 mm in length and 256 mm in diameter. We have no fewer than seven advanced machines. Our automated production process guarantees short delivery times and the highest quality. Whether your tubes and pipes are made from (stainless) steel or aluminum, they’re in good hands with our experts!

Would you like to know more about the tube-laser-cutting options we are able to offer?

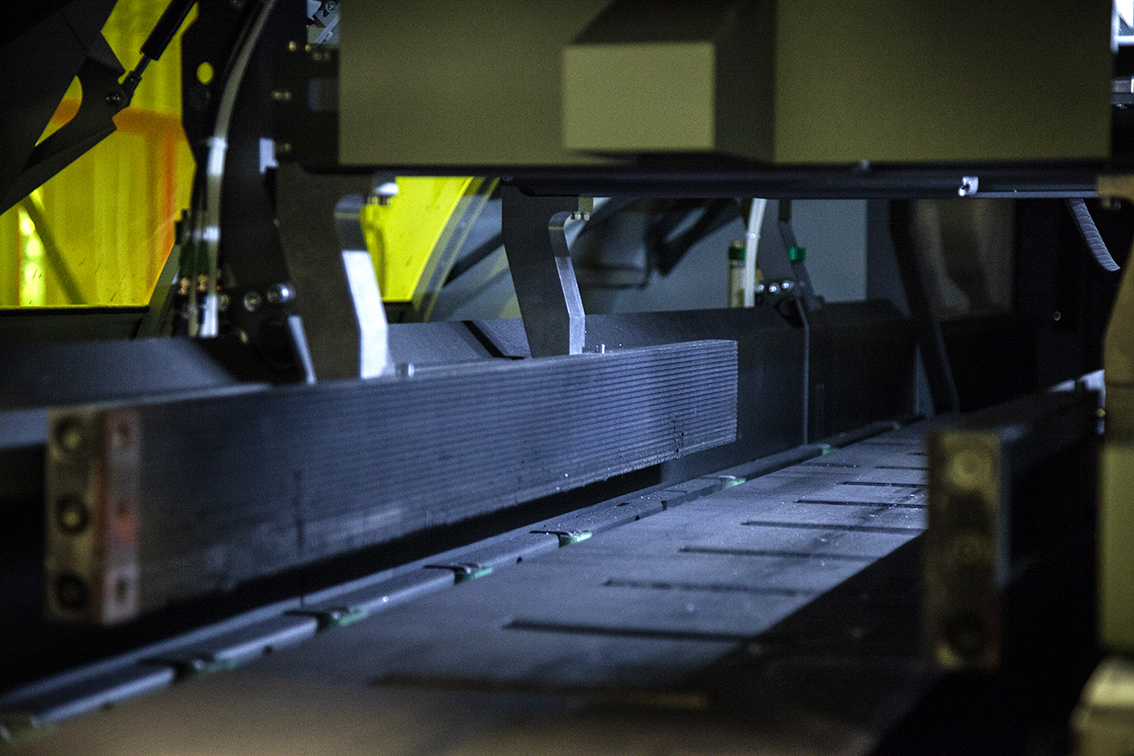

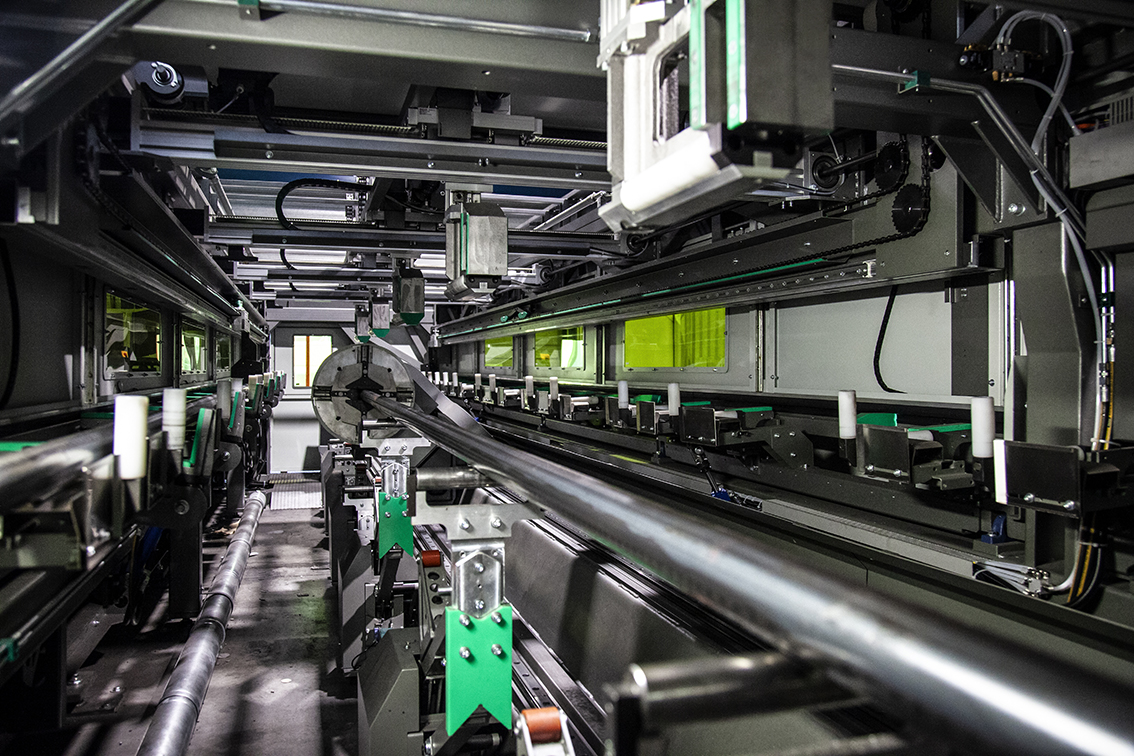

Our advanced machines

| Trumpf |

| Adige LT-7: possible to automatically load special profiles |

| Adige LT-8: suitable for small series |

| Adige LT-8.10: possible to switch quickly between different products |

| Adige LT Fiber: suitable for big series |

Advantages of tube-laser cutting at Dumaco

Dumaco is the leading expert in sheet-metal processing. From laser cutting to (robotic) welding. For the processing of your tubes and pipes too! Our years of experience and the very latest technology guarantee quality. We believe that collaboration is the secret to a good product. So, our experts communicate with you to ensure you get the end product you have in mind. When doing this, we always consider the need for a sustainable design, wasting as little material as possible.

From design to end product

As the customer, you design the product yourself, choose the type of material to be used and supply the design in the form of a 3D drawing. Next, it’s over to our specialists to turn your design into an excellent end product. Naturally, we will share our thoughts and ideas with you in every phase, including the design phase. Would you like to submit a 3D design? If so, see the conditions below. Please contact us if you have any questions.

The advantages at a glance

| High precision due to automated machines |

| Productivity advantages from post-processing |

| Fast production and series production possible |

| Series production cheaper |

| Tube-laser cutting up to lengths of 6.5 meters |

Tube-laser cutting

This is tube-laser cutting

Tube-laser cutting involves the use of a laser beam to process long metal profiles into a finished product or semi-finished product. We mainly use nitrogen when laser cutting. This avoids the generation of an oxide layer, which is important if the cut pieces have to be coated as well. The use of nitrogen while cutting enables us to cut steel with a wall thickness of 5 mm or more.

Tube-laser cutting versus drilling and sawing

Laser-cutting tubes and pipes has advantages over ‘traditional’ methods like sawing and drilling. In actual fact, laser cutting technology is replacing a number of operations, making it possible to achieve improved speed and precision. The high production speed also paves the way for a big reduction in your total production costs.

Different tube-laser-cutting methods

Bij Dumaco kunt u op drie verschillende manieren buislaseren. Neem contact op met onze experts om te kijken welke methode het meest geschikt is voor uw project.

- 90°-snijden. Alle contouren worden haaks (90°) op het buisoppervlak gesneden en de buis of koker roteert onder lasersnijkop door. Hierdoor ontstaat er loodrecht op de wanddikte een snede. Dit is de meeste eenvoudige en snelle manier van snijden en dus zeer kostenefficiënt .

- XY-snijden. Bij het snijden beweegt de lasersnijkop langs de X- en Y as over de koker. Hierdoor ontstaat er een snede loodrecht op het horizontale vlak. Deze methode is extra nauwkeurig, maar valt daarom ook hoger uit qua productietijd en kosten.

- 2.5D snijden. Er wordt gebruikt gemaakt van alle mogelijk assen van de machine, inclusief het kantelen van de lasersnijkop. Dit maakt het mogelijk om contouren onder een hoek van maximaal 45° te snijden. Dit heeft wederom invloed op de snijsnelheid en de uiteindelijke kosten.

Standard quotations are always issued within 24 hours

Standard quotations are always issued within 24 hours